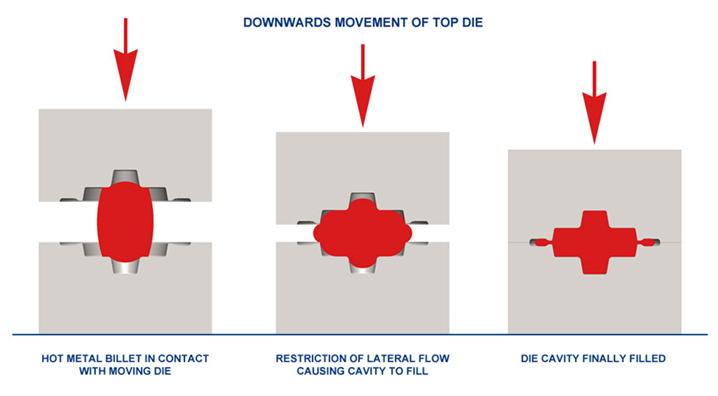

Drop Forging / Closed Die Forging

Drop Forging / Closed die forging is a manufacturing process in which a work piece is shaped by pressing it between two dies that are brought together with great force. The dies are typically made of hardened steel and are designed to impart a specific shape to the work piece. The process is called "closed die" forging because the dies are closed around the work piece, forming a confined space in which the forging takes place.

In closed die forging, the work piece is typically heated to a high temperature before it is placed between the dies. This helps to make the material more malleable, allowing it to be shaped more easily. The dies are then brought together with great force, typically using a press or hammer. The force and pressure applied to the work piece causes it to take on the shape of the dies.

Closed die forging is a common manufacturing process that is used to produce a wide variety of metal parts, including gears, shafts, automotive components as well as for the production of flanges and other piping components.. It is a useful process because it allows for the production of complex, high-strength parts that are not easily produced using other manufacturing methods.

Components manufactured using the drop forging process are stronger than their equivalent machined from solid or cast parts.

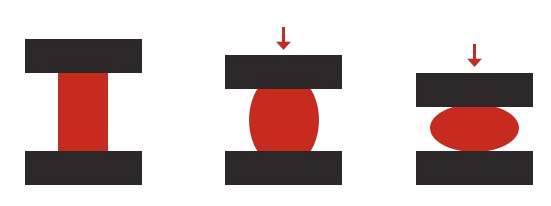

Open Die Forging

Open die forging is a forging process in which a piece of hot metal is shaped by pressing or pounding it between a series of flat or partially-shaped dies. Unlike closed die forging, which uses fully enclosed dies to shape the metal, open die forging allows the metal to be shaped in a more flexible and custom way.

Open die forging is typically used to produce large, complex parts that require a high degree of customization or that cannot be produced using other forging methods. It is often used to produce parts for the aerospace, defense, and heavy machinery industries, as well as for the production of custom flanges and other piping components.

In open die forging, the metal is heated until it is hot enough to be shaped by the dies. It is then placed between the dies and struck with a hammer or press to shape it. The dies are typically made from a high-strength tool steel and are carefully machined to produce the desired shape.

The goal is to shape the metal into the desired shape while maintaining its strength & integrity.