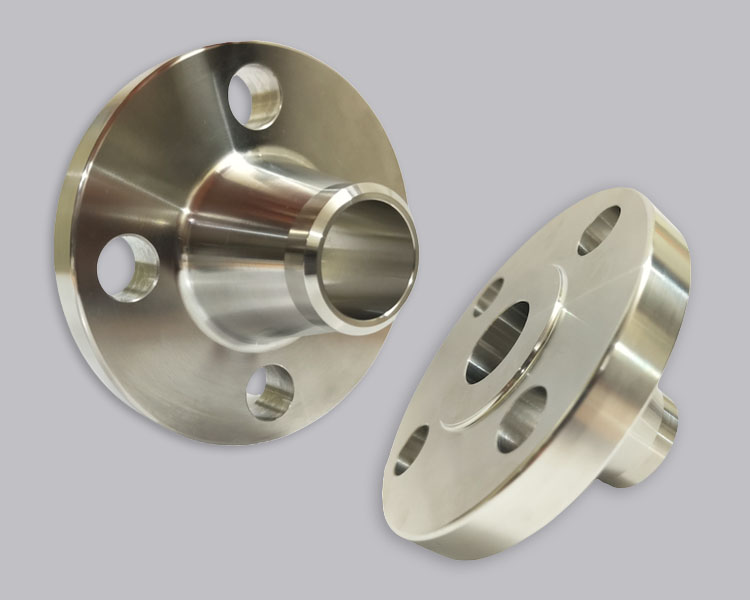

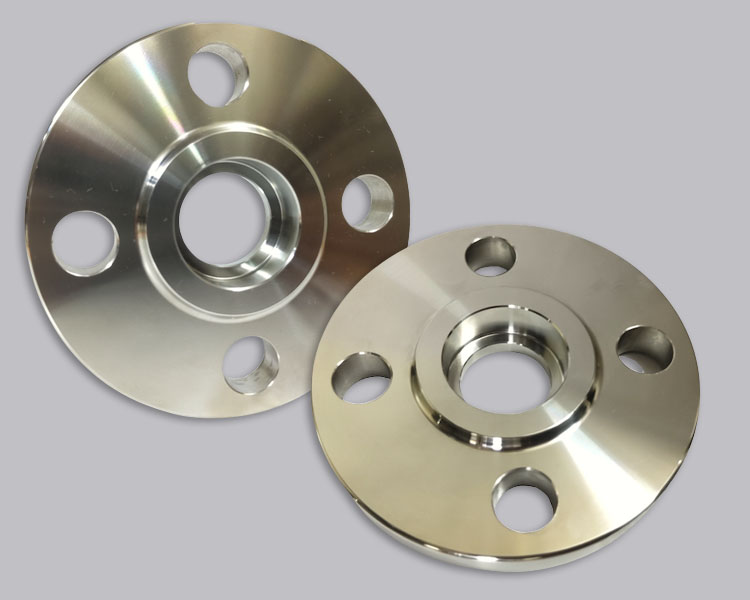

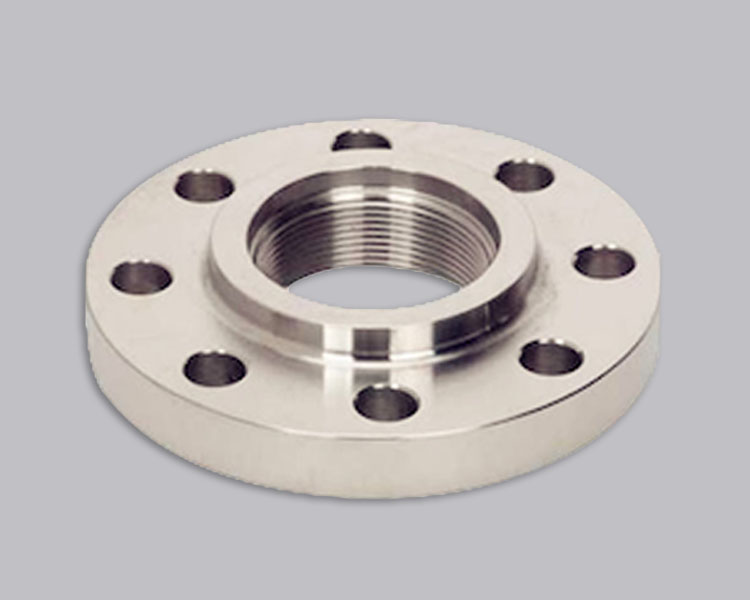

Our state-of-the-art manufacturing facility is equipped with the latest technology and equipment, allowing us to produce a wide range of flanges in a variety of materials, including Carbon steel, Stainless Steel, Alloy Steel, Copper Alloy and Nickel Alloy.

We use advanced forging techniques to ensure the strength and integrity of our flanges, and we subject them to rigorous testing to ensure they meet the required quality standards.

In addition to meeting the required standards, we are also committed to providing excellent customer service and technical support. Our team of experienced engineers is available to assist with the design and selection of flanges to meet the specific needs of our customers.

Whether you are in need of a single flange or a large order, we have the expertise and capacity to meet your needs. Contact us today to learn more about how we can help you with your flange requirements.